Crafting The Future: 3D Printing In Jewelry Design

Crafting the Future: 3D Printing in Jewelry Design

Related Articles: Crafting the Future: 3D Printing in Jewelry Design

Introduction

With great pleasure, we will explore the intriguing topic related to Crafting the Future: 3D Printing in Jewelry Design. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

Crafting the Future: 3D Printing in Jewelry Design

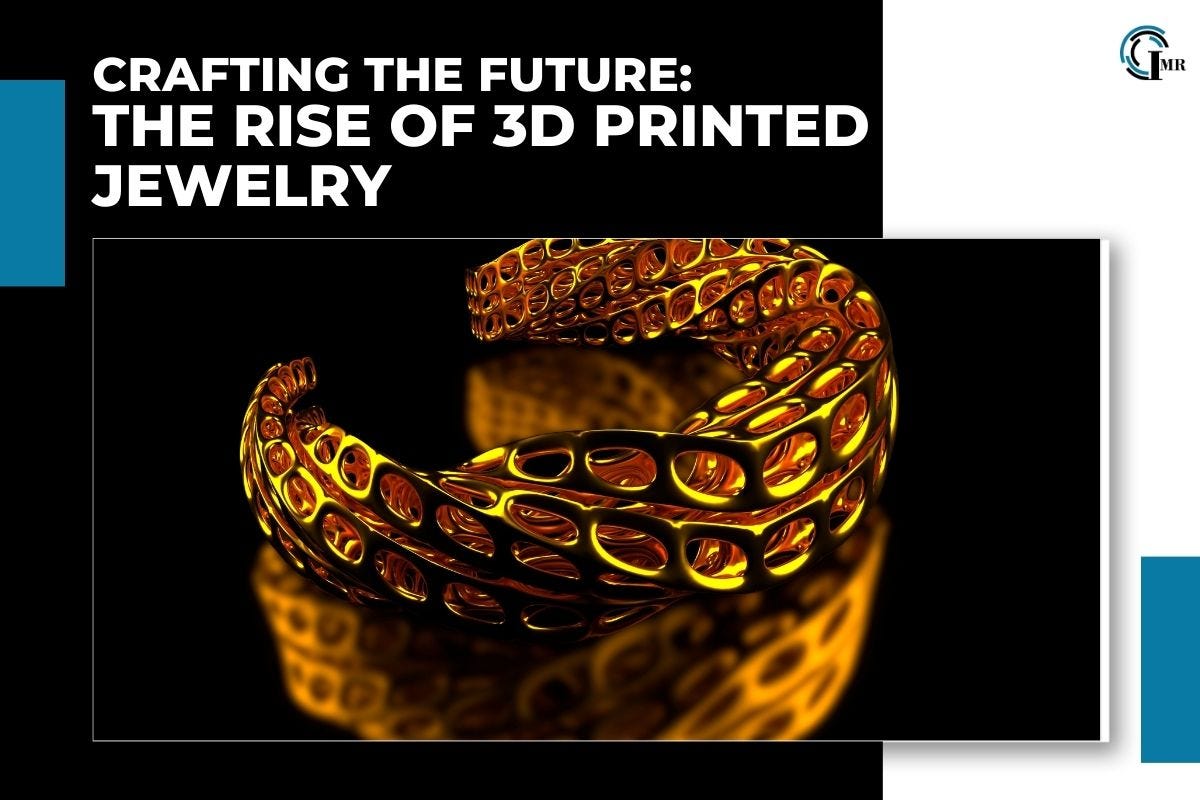

The world of jewelry design has undergone a dramatic transformation with the advent of 3D printing technology. No longer bound by traditional methods, designers and artisans are leveraging this innovative tool to create intricate, personalized, and sustainable pieces that push the boundaries of artistic expression.

A New Paradigm in Jewelry Creation

3D printing, also known as additive manufacturing, offers a distinct advantage over traditional methods like casting or handcrafting. Instead of removing material, it builds objects layer by layer from a digital model, allowing for unprecedented levels of detail and complexity. This opens up a universe of possibilities for jewelry designers, enabling them to:

- Realize intricate designs: 3D printing allows for the creation of complex geometries, intricate patterns, and delicate filigree work that would be impossible or extremely time-consuming using traditional techniques.

- Explore innovative materials: The technology allows for the use of a wide range of materials, including precious metals, resins, ceramics, and even biodegradable plastics, expanding the creative palette for jewelry designers.

- Create custom pieces: 3D printing empowers designers to personalize jewelry to individual preferences, allowing for unique pieces tailored to specific body shapes, sizes, and aesthetics.

- Reduce waste and promote sustainability: 3D printing minimizes material waste compared to traditional methods, contributing to a more sustainable jewelry industry.

- Prototype quickly and efficiently: Designers can quickly iterate and experiment with different designs, saving time and resources in the prototyping phase.

3D Printing Technologies for Jewelry

Several 3D printing technologies are employed in jewelry design, each with its unique characteristics and applications:

- Stereolithography (SLA): This technology uses a UV laser to cure liquid photopolymer resin, creating highly detailed and smooth jewelry pieces. SLA is ideal for intricate designs and delicate features.

- Selective Laser Sintering (SLS): SLS uses a laser to fuse powdered materials, such as nylon or metal, layer by layer. This method is known for its strength and durability, making it suitable for larger and more robust jewelry pieces.

- Fused Deposition Modeling (FDM): FDM uses a heated nozzle to extrude thermoplastic filament, layer by layer, to build the desired shape. While offering lower cost and versatility, FDM is generally less precise than SLA or SLS and may leave visible layer lines.

- Direct Metal Laser Sintering (DMLS): This advanced technology uses a high-power laser to fuse metal powder, enabling the creation of highly detailed and durable jewelry pieces in precious metals like gold, silver, and platinum.

Choosing the Right 3D Printing Technology

Selecting the appropriate 3D printing technology for jewelry design depends on various factors, including:

- Design complexity: Intricate designs with fine details typically require technologies like SLA or DMLS.

- Material requirements: The desired material, whether precious metal, resin, or plastic, dictates the appropriate printing technology.

- Budget: The cost of 3D printing can vary significantly depending on the technology and material used.

- Production volume: For small-scale production, SLA or SLS may be suitable, while DMLS is more appropriate for larger production runs.

The Benefits of 3D Printing in Jewelry Design

The impact of 3D printing on the jewelry industry extends beyond mere technological advancement. It offers a multitude of benefits, including:

- Enhanced creativity and innovation: 3D printing allows designers to experiment with complex geometries, intricate patterns, and unique designs that would be impossible or impractical with traditional methods.

- Personalized jewelry: With 3D printing, designers can create custom pieces tailored to individual preferences, ensuring a unique and personal touch.

- Reduced production time and cost: 3D printing streamlines the design and prototyping process, leading to faster turnaround times and reduced production costs.

- Sustainable practices: 3D printing minimizes material waste and allows for the use of recycled materials, promoting a more environmentally friendly approach to jewelry production.

- Accessibility and democratization: 3D printing lowers the barrier to entry for aspiring jewelry designers, enabling them to create and sell their designs without significant capital investment.

FAQs About 3D Printing in Jewelry

1. Is 3D printed jewelry durable?

The durability of 3D printed jewelry depends on the printing technology and material used. SLA and SLS can produce durable pieces, while FDM may require additional post-processing for enhanced strength.

2. Can 3D printed jewelry be set with gemstones?

Yes, 3D printed jewelry can be set with gemstones. Designers can incorporate pre-designed settings or create custom settings using 3D printing.

3. What are the limitations of 3D printing in jewelry?

While 3D printing offers numerous benefits, it also has limitations. Some technologies may produce visible layer lines, and the achievable level of detail can vary depending on the printing technology.

4. Can 3D printed jewelry be polished and finished?

Yes, 3D printed jewelry can be polished and finished to achieve a smooth and lustrous surface. The finishing process may vary depending on the material and printing technology used.

5. How much does 3D printed jewelry cost?

The cost of 3D printed jewelry varies depending on factors such as the printing technology, material, design complexity, and production volume.

Tips for Designing Jewelry with 3D Printing

- Start with a clear design concept: Before beginning the design process, define the overall aesthetic and desired functionality of the jewelry piece.

- Utilize design software: Employ 3D modeling software to create detailed and accurate designs.

- Consider the printing technology and material: Choose a technology and material that best suit the design complexity and desired characteristics of the jewelry piece.

- Prototype and iterate: Create prototypes to refine the design and ensure its feasibility before committing to final production.

- Optimize for 3D printing: Design with 3D printing in mind, considering factors like overhangs, supports, and print orientation.

Conclusion

3D printing has revolutionized the jewelry industry, empowering designers to create intricate, personalized, and sustainable pieces that push the boundaries of creativity. By leveraging the power of this technology, designers can explore new materials, experiment with complex geometries, and create unique pieces tailored to individual preferences. As 3D printing technology continues to evolve, we can expect even more innovative and groundbreaking jewelry designs to emerge, shaping the future of this timeless art form.

Closure

Thus, we hope this article has provided valuable insights into Crafting the Future: 3D Printing in Jewelry Design. We appreciate your attention to our article. See you in our next article!