Crafting The Future: 3D Printing’s Impact On Jewelry Design And Production

Crafting the Future: 3D Printing’s Impact on Jewelry Design and Production

Related Articles: Crafting the Future: 3D Printing’s Impact on Jewelry Design and Production

Introduction

With great pleasure, we will explore the intriguing topic related to Crafting the Future: 3D Printing’s Impact on Jewelry Design and Production. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

- 1 Related Articles: Crafting the Future: 3D Printing’s Impact on Jewelry Design and Production

- 2 Introduction

- 3 Crafting the Future: 3D Printing’s Impact on Jewelry Design and Production

- 3.1 Understanding 3D Printing for Jewelry

- 3.2 Benefits of 3D Printing for Jewelry

- 3.3 Applications of 3D Printing in Jewelry

- 3.4 FAQs about 3D Printing for Jewelry

- 3.5 Tips for Success in 3D Printing Jewelry

- 3.6 Conclusion

- 4 Closure

Crafting the Future: 3D Printing’s Impact on Jewelry Design and Production

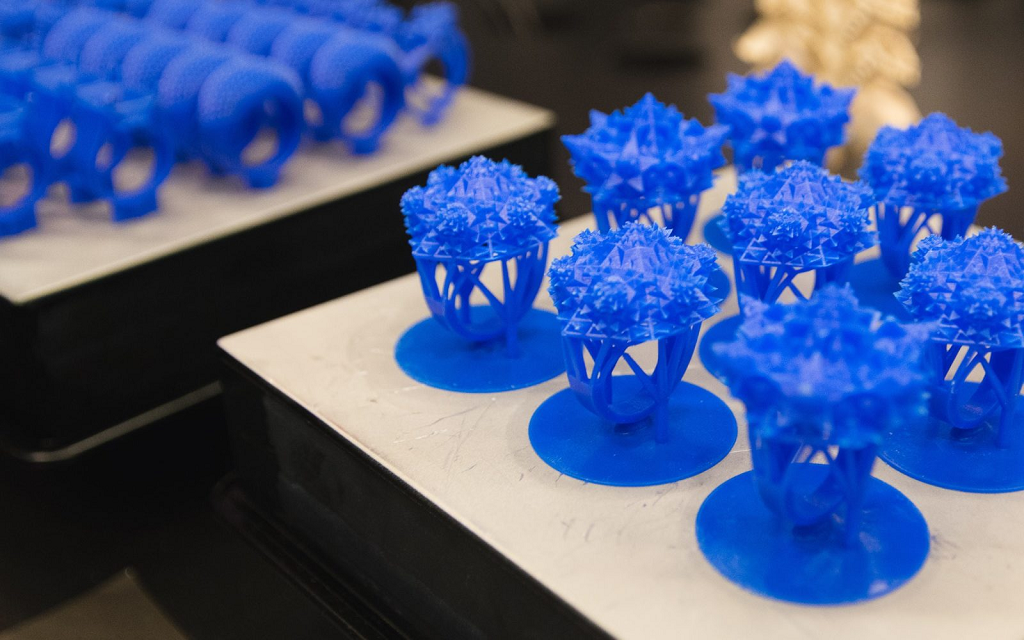

The jewelry industry, steeped in tradition and craftsmanship, has undergone a transformative evolution with the advent of 3D printing. This technology, once confined to industrial applications, has emerged as a potent tool for jewelry designers and makers, revolutionizing the way pieces are conceptualized, crafted, and brought to life.

This article delves into the multifaceted world of 3D printing for jewelry, exploring its significance, benefits, and the diverse applications it encompasses. It aims to provide a comprehensive understanding of this technology’s role in shaping the future of the jewelry industry.

Understanding 3D Printing for Jewelry

At its core, 3D printing, also known as additive manufacturing, involves building three-dimensional objects layer by layer from a digital model. This process utilizes specialized materials, ranging from plastics and resins to precious metals, to create intricate designs with unparalleled precision and detail.

How it Works:

-

Digital Design: The journey begins with a digital design, typically created using computer-aided design (CAD) software. This software empowers designers to craft intricate geometries, textures, and patterns, pushing the boundaries of traditional jewelry design.

-

Slicing: The digital design is then sliced into thin cross-sections, forming a series of instructions for the 3D printer. This slicing process converts the design into a format the printer can understand.

-

Material Deposition: The 3D printer, guided by the sliced instructions, meticulously deposits layers of material, fusing them together to create the final three-dimensional object. This process can be compared to building a structure brick by brick, with each layer adding to the overall form.

Types of 3D Printers for Jewelry:

The jewelry industry utilizes various types of 3D printers, each suited to specific needs and materials:

-

Fused Deposition Modeling (FDM): This technology, commonly used for prototyping, utilizes thermoplastic filaments that are extruded through a heated nozzle, layer by layer. While cost-effective, FDM prints may exhibit visible layer lines and require post-processing to achieve a smooth finish.

-

Stereolithography (SLA): SLA printers employ a vat of liquid photopolymer resin, which is selectively cured by a UV laser beam, solidifying the resin into the desired shape. This process yields high-resolution prints with smooth surfaces and intricate details, making it ideal for intricate jewelry designs.

-

Selective Laser Melting (SLM): This technology, suitable for metal jewelry, uses a high-powered laser to melt and fuse powdered metal materials, layer by layer, directly into the desired shape. SLM offers exceptional precision and detail, allowing for the creation of intricate, durable, and highly detailed metal jewelry.

-

Direct Metal Laser Sintering (DMLS): Similar to SLM, DMLS utilizes a laser to fuse powdered metal materials, but instead of melting, it sinters the powder particles together, creating a strong and durable structure. This process allows for the creation of intricate metal jewelry with complex geometries.

Benefits of 3D Printing for Jewelry

The adoption of 3D printing in the jewelry industry has ushered in a new era of design freedom and manufacturing efficiency, offering numerous benefits:

-

Design Freedom and Customization: 3D printing liberates designers from the constraints of traditional jewelry-making techniques, allowing them to explore intricate geometries, complex shapes, and innovative designs that were previously impossible to achieve. This technology empowers designers to create unique and personalized pieces, catering to individual preferences and styles.

-

Rapid Prototyping and Iteration: 3D printing enables rapid prototyping, allowing designers to quickly create physical models of their designs and test different variations, facilitating faster iteration and refinement. This accelerated prototyping process enables designers to explore and refine their ideas efficiently, reducing time to market and increasing design innovation.

-

Reduced Production Costs and Lead Times: 3D printing can streamline the manufacturing process, eliminating the need for expensive molds and tooling, which are often required in traditional jewelry production. This reduction in tooling costs translates to lower production costs and shorter lead times, making it a cost-effective option for both large-scale production and small-batch runs.

-

Sustainable Production: 3D printing promotes sustainable production practices by minimizing material waste. The additive nature of the process allows for the creation of intricate designs with minimal material usage, reducing waste compared to traditional subtractive manufacturing methods.

-

Enhanced Detail and Precision: 3D printing delivers exceptional detail and precision, allowing for the creation of intricate jewelry pieces with fine textures, delicate patterns, and intricate geometries. This level of detail enables the creation of highly realistic and visually stunning pieces.

-

New Material Exploration: 3D printing opens up a world of new materials for jewelry creation, including biocompatible materials, precious metals, and even composites. This expands the possibilities for designers to experiment with various materials and create unique and innovative jewelry pieces.

Applications of 3D Printing in Jewelry

3D printing has found widespread applications across the jewelry industry, revolutionizing various aspects of design, production, and even retail:

-

Prototyping and Design Exploration: Designers leverage 3D printing to quickly create physical models of their designs, allowing them to visualize their ideas in three dimensions and test different variations before committing to final production. This accelerates the design process and reduces the risk of costly errors.

-

Production of Custom Jewelry: 3D printing excels in creating personalized jewelry pieces, allowing for the creation of unique designs tailored to individual preferences. This technology empowers designers to create custom rings, earrings, pendants, and other jewelry pieces that reflect the wearer’s unique style.

-

Production of Limited Edition and High-End Jewelry: 3D printing enables the creation of limited edition and high-end jewelry pieces with intricate designs and complex geometries, often incorporating precious metals and gemstones. This technology allows for the production of unique and exclusive pieces that cater to discerning customers.

-

Production of Investment Casting Molds: 3D printing plays a crucial role in investment casting, a traditional jewelry-making technique. 3D printed molds offer exceptional detail and precision, enabling the creation of highly intricate and complex jewelry pieces.

-

Jewelry Retail and Customization: 3D printing is transforming the way jewelry is sold and customized. Consumers can use 3D printing to create custom jewelry pieces based on their own designs, or select from a wide range of pre-designed models and personalize them with their own initials, engravings, or other embellishments.

FAQs about 3D Printing for Jewelry

Q: What materials can be used for 3D printing jewelry?

A: 3D printing for jewelry utilizes a diverse range of materials, including:

- Plastics and Resins: These materials are commonly used for prototyping and creating affordable jewelry pieces.

- Metals: 3D printing with metals, such as silver, gold, platinum, and titanium, enables the creation of durable and valuable jewelry pieces.

- Ceramics: 3D printing with ceramics allows for the creation of intricate and durable jewelry pieces with unique textures and finishes.

Q: What are the limitations of 3D printing for jewelry?

A: While 3D printing offers numerous advantages, it also has some limitations:

- Size and Shape Constraints: 3D printers have limitations in terms of the size and complexity of objects they can print. Larger and more complex jewelry pieces may require specialized equipment or multiple printing sessions.

- Post-Processing: 3D printed jewelry often requires post-processing steps, such as smoothing, polishing, and finishing, to achieve the desired aesthetic and durability.

- Material Availability: The availability of suitable materials for 3D printing jewelry is still evolving, and some materials may not be readily available or affordable.

Q: Is 3D printed jewelry durable?

A: The durability of 3D printed jewelry depends on the material used and the printing process. 3D printed jewelry made from metals, such as silver, gold, or platinum, can be as durable as traditionally made jewelry. However, jewelry made from plastics or resins may be less durable and require more careful handling.

Q: How much does it cost to 3D print jewelry?

A: The cost of 3D printing jewelry varies depending on the material, size, complexity, and quantity of the piece. 3D printing can be a cost-effective option for small-batch production, but for large-scale production, it may be more cost-effective to use traditional manufacturing methods.

Tips for Success in 3D Printing Jewelry

- Choose the Right Printer and Material: Select a 3D printer and material that best suit your specific design requirements, budget, and production volume.

- Master CAD Software: Proficiency in CAD software is essential for creating detailed and accurate digital models for 3D printing.

- Optimize Your Designs: Optimize your designs for 3D printing to ensure optimal print quality and minimize material waste.

- Invest in Post-Processing Equipment: Invest in tools and equipment for post-processing, such as sanding, polishing, and finishing, to achieve the desired aesthetic and durability.

- Experiment and Iterate: Don’t be afraid to experiment with different materials, designs, and printing techniques to find what works best for you.

Conclusion

3D printing has emerged as a transformative force in the jewelry industry, empowering designers and makers to create unique and innovative pieces. This technology offers unparalleled design freedom, rapid prototyping, reduced production costs, and enhanced detail and precision, enabling the creation of custom, limited edition, and high-end jewelry. As 3D printing technology continues to evolve and materials become more readily available, its impact on the jewelry industry will only grow, shaping the future of jewelry design and production.

Closure

Thus, we hope this article has provided valuable insights into Crafting the Future: 3D Printing’s Impact on Jewelry Design and Production. We thank you for taking the time to read this article. See you in our next article!