The Art Of Precision: Unlocking The Potential Of 3D Jewelry Design Services

The Art of Precision: Unlocking the Potential of 3D Jewelry Design Services

Related Articles: The Art of Precision: Unlocking the Potential of 3D Jewelry Design Services

Introduction

With great pleasure, we will explore the intriguing topic related to The Art of Precision: Unlocking the Potential of 3D Jewelry Design Services. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Art of Precision: Unlocking the Potential of 3D Jewelry Design Services

In the realm of jewelry creation, the traditional methods of handcrafting and sketching have long been the foundation of artistry. However, the advent of 3D jewelry design services has revolutionized the industry, ushering in a new era of precision, innovation, and accessibility.

This transformative technology empowers jewelers, designers, and enthusiasts alike to transcend the limitations of traditional methods, enabling them to conceptualize, visualize, and bring to life intricate and imaginative jewelry pieces with unparalleled accuracy and detail.

Understanding 3D Jewelry Design Services: A Comprehensive Overview

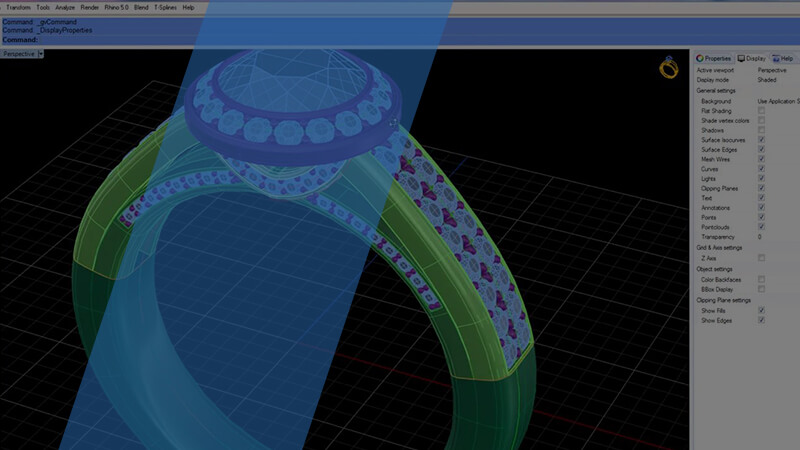

3D jewelry design services encompass a range of digital tools and techniques that enable the creation of virtual representations of jewelry pieces. These services leverage advanced software programs, such as Rhinoceros, Maya, and ZBrush, to construct intricate 3D models, capturing every facet, curve, and detail with remarkable precision.

The Benefits of Embracing 3D Jewelry Design Services

The adoption of 3D jewelry design services brings forth a myriad of advantages, transforming the jewelry creation process into a seamless and efficient journey:

-

Enhanced Visualization and Communication: 3D models provide a tangible representation of the jewelry design, allowing designers to visualize the final product before committing to physical production. This facilitates clear communication with clients, ensuring a shared understanding of the design intent and minimizing the risk of misinterpretations.

-

Unparalleled Precision and Detail: 3D modeling software empowers designers to achieve intricate details, complex geometries, and intricate settings that would be challenging or impossible to replicate through traditional methods. This precision translates into exquisite jewelry pieces that showcase the artistry and craftsmanship of the designer.

-

Reduced Production Costs and Time: 3D printing technology allows for rapid prototyping, enabling designers to experiment with different designs and materials before committing to full-scale production. This significantly reduces production costs and time, allowing for faster turnaround times and increased efficiency.

-

Increased Creativity and Innovation: 3D design services liberate designers from the constraints of traditional techniques, opening up a world of possibilities for innovative and unique jewelry creations. Designers can experiment with unconventional shapes, textures, and materials, pushing the boundaries of jewelry design.

-

Sustainable and Eco-Friendly Practices: 3D printing technology minimizes material waste, reducing the environmental impact of jewelry production. This aligns with the growing awareness of sustainability and responsible practices within the jewelry industry.

The Process of 3D Jewelry Design Services: A Step-by-Step Guide

The process of utilizing 3D jewelry design services typically involves the following steps:

-

Initial Consultation: The designer and client collaborate to discuss the desired design, materials, and budget. This stage is crucial for establishing clear expectations and ensuring the design aligns with the client’s vision.

-

Concept Development and Sketching: The designer develops initial sketches or rough 3D models to illustrate the basic design concept. This provides a visual framework for the final 3D model.

-

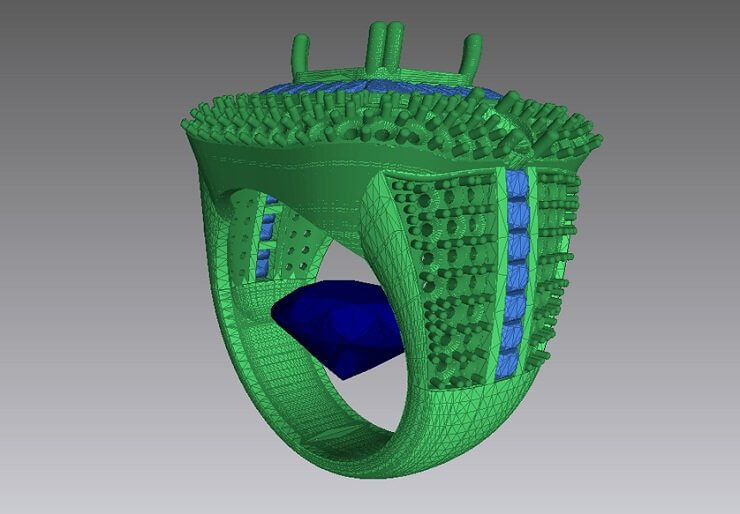

3D Modeling: The designer meticulously creates the 3D model using specialized software, incorporating all the details and specifications discussed during the consultation.

-

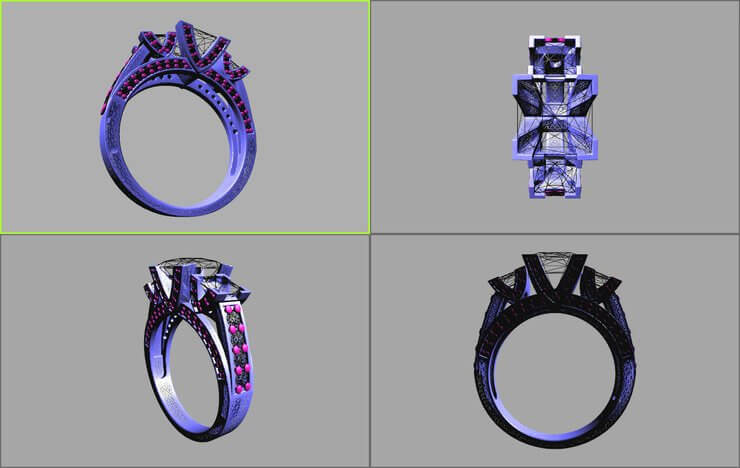

Rendering and Visualization: The 3D model is rendered in high-resolution images or animations, providing a realistic representation of the final product.

-

Client Approval and Refinement: The designer presents the rendered images or animations to the client for approval. If necessary, the design can be refined based on client feedback.

-

3D Printing or Casting: Once the design is finalized, the 3D model can be printed using a 3D printer or cast using traditional jewelry casting techniques.

-

Finishing and Polishing: The 3D printed or cast piece is finished and polished to achieve the desired look and feel.

FAQs: Addressing Common Queries about 3D Jewelry Design Services

1. What types of jewelry can be designed using 3D technology?

3D design services can be employed to create a wide range of jewelry, including rings, earrings, necklaces, bracelets, pendants, and more. The technology is particularly well-suited for intricate designs, complex geometries, and custom pieces.

2. What materials can be used for 3D printed or cast jewelry?

A variety of materials can be used for 3D printed or cast jewelry, including precious metals (gold, silver, platinum), resin, wax, and ceramic. The choice of material depends on the design, budget, and desired aesthetic.

3. How much do 3D jewelry design services cost?

The cost of 3D jewelry design services can vary depending on the complexity of the design, the materials used, and the service provider. It is advisable to obtain quotes from multiple providers to compare pricing and services.

4. What are the benefits of using 3D printing for jewelry production?

3D printing offers several benefits for jewelry production, including:

- Rapid Prototyping: 3D printing allows for quick and efficient prototyping, enabling designers to test different designs and materials before committing to full-scale production.

- Reduced Waste: 3D printing minimizes material waste, making it a more sustainable and environmentally friendly option.

- Complex Designs: 3D printing can produce intricate and complex designs that would be difficult or impossible to create using traditional methods.

5. What is the difference between 3D printing and casting?

3D printing and casting are two different methods of jewelry production:

- 3D Printing: Involves building up a 3D object layer by layer using a 3D printer. This process is ideal for creating intricate designs and prototypes.

- Casting: Involves pouring molten metal into a mold to create a replica of the original design. Casting is a more traditional method that is suitable for high-volume production.

Tips for Choosing a 3D Jewelry Design Service Provider

- Research and Compare: Explore different service providers and compare their portfolios, pricing, and customer reviews.

- Clear Communication: Ensure that the service provider is responsive and communicates clearly throughout the design process.

- Portfolio Review: Review the provider’s portfolio to assess their design capabilities and aesthetic style.

- Client Testimonials: Seek out client testimonials and reviews to gain insights into the provider’s professionalism and customer satisfaction.

- Consultation and Collaboration: Choose a provider who prioritizes client consultation and collaboration, ensuring that the final design meets your specific needs and preferences.

Conclusion: Embracing the Future of Jewelry Design

3D jewelry design services represent a significant advancement in the jewelry industry, empowering designers and clients alike to create and experience jewelry in a whole new way. This transformative technology offers unparalleled precision, detail, and efficiency, while fostering creativity and innovation. As technology continues to evolve, we can expect to see even more groundbreaking advancements in 3D jewelry design, further blurring the lines between imagination and reality.

Closure

Thus, we hope this article has provided valuable insights into The Art of Precision: Unlocking the Potential of 3D Jewelry Design Services. We hope you find this article informative and beneficial. See you in our next article!