The Future Of Jewelry Design: 3D Printing In Mount Pearl

The Future of Jewelry Design: 3D Printing in Mount Pearl

Related Articles: The Future of Jewelry Design: 3D Printing in Mount Pearl

Introduction

With great pleasure, we will explore the intriguing topic related to The Future of Jewelry Design: 3D Printing in Mount Pearl. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

- 1 Related Articles: The Future of Jewelry Design: 3D Printing in Mount Pearl

- 2 Introduction

- 3 The Future of Jewelry Design: 3D Printing in Mount Pearl

- 3.1 3D Printing: A New Dimension in Jewelry Creation

- 3.2 The Impact of 3D Printing on Jewelry Design in Mount Pearl

- 3.3 FAQs about 3D Printed Jewelry in Mount Pearl

- 3.4 Tips for Choosing 3D Printed Jewelry in Mount Pearl

- 3.5 Conclusion

- 4 Closure

The Future of Jewelry Design: 3D Printing in Mount Pearl

The world of jewelry design is undergoing a revolution, driven by the innovative power of 3D printing technology. This transformative technology allows jewelers to create intricate and personalized pieces with unprecedented precision and detail, pushing the boundaries of traditional crafting methods. In Mount Pearl, this technological advancement is shaping the future of jewelry design, offering a unique blend of artistry and innovation.

3D Printing: A New Dimension in Jewelry Creation

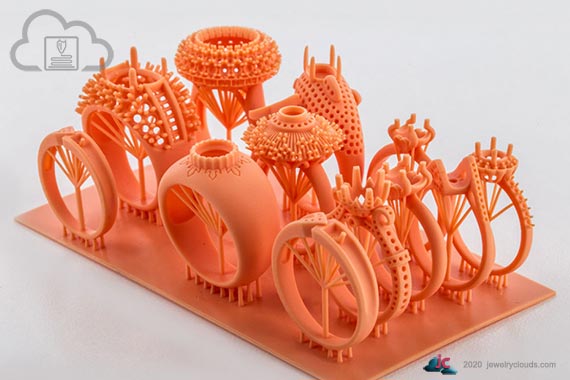

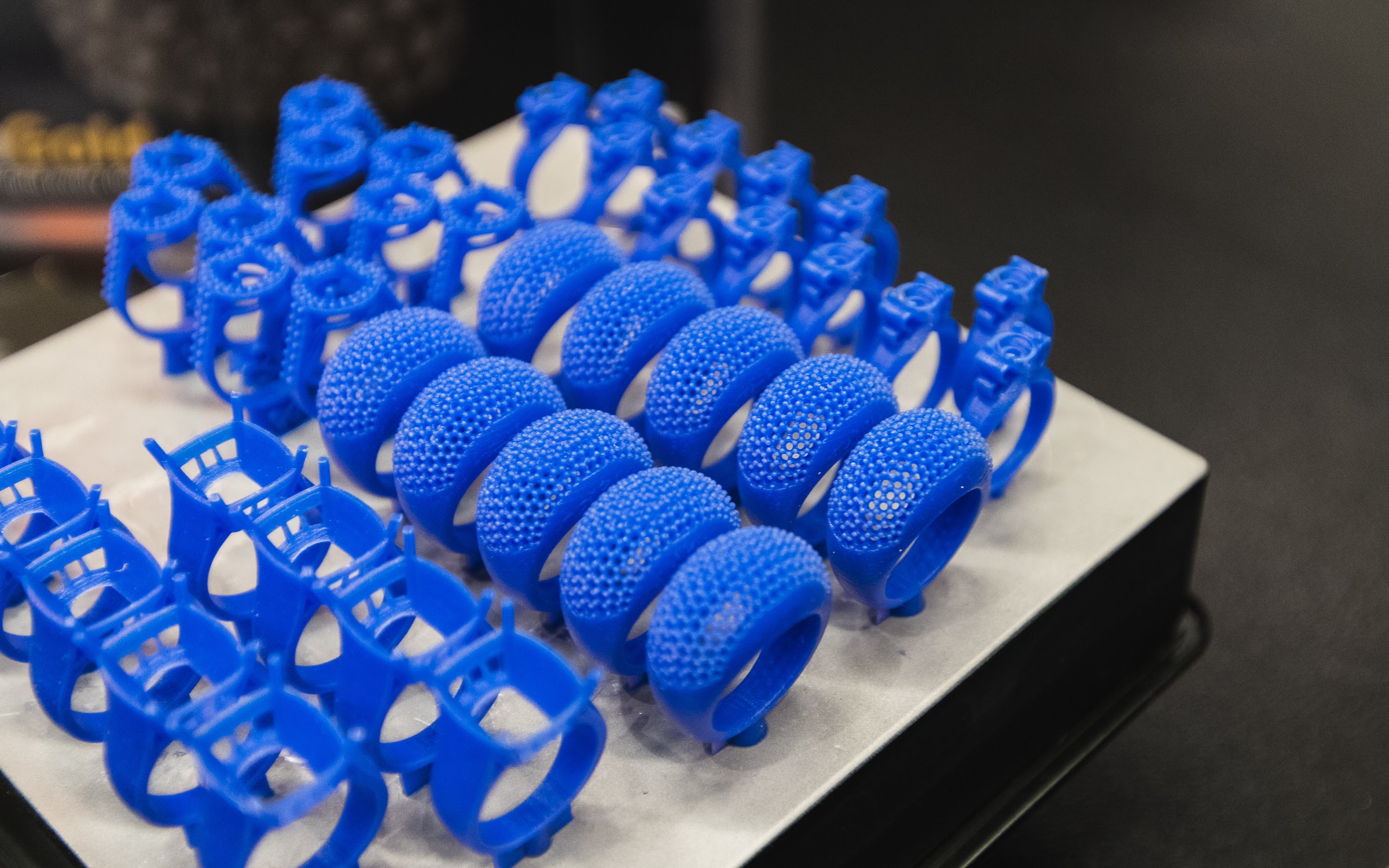

3D printing, also known as additive manufacturing, utilizes a layer-by-layer approach to build three-dimensional objects from a digital design. This process involves a computer-aided design (CAD) software program that translates the design into a digital file. The file is then sent to a 3D printer, which uses a variety of materials, including precious metals, resins, and ceramics, to construct the object.

This technology offers a myriad of advantages for jewelers in Mount Pearl:

1. Unparalleled Precision and Detail: 3D printing allows for intricate designs and complex geometries that are difficult or impossible to achieve through traditional methods. This opens up a world of possibilities for creating unique and eye-catching jewelry pieces.

2. Personalized Designs: 3D printing enables the creation of personalized jewelry, tailored to individual preferences and styles. Customers can collaborate with jewelers to design custom pieces, from engagement rings to pendants, incorporating their unique ideas and specifications.

3. Reduced Production Time and Costs: The 3D printing process eliminates the need for traditional molds and casting, significantly reducing production time and costs. This allows jewelers to offer competitive pricing and faster turnaround times for their clients.

4. Sustainable Practices: 3D printing minimizes material waste compared to traditional methods, making it a more sustainable option for jewelry production.

5. Exploration of New Materials: 3D printing allows jewelers to experiment with a wider range of materials, including exotic metals, biocompatible materials, and even recycled materials. This opens up a new frontier of design possibilities and allows for the creation of unique and innovative jewelry pieces.

The Impact of 3D Printing on Jewelry Design in Mount Pearl

The adoption of 3D printing technology is transforming the jewelry industry in Mount Pearl, empowering jewelers to create unique and personalized pieces that cater to the diverse tastes of their customers.

1. Rise of Independent Designers: 3D printing allows aspiring designers to create and showcase their work without the need for expensive equipment or traditional manufacturing processes. This fosters a vibrant and competitive environment, promoting innovation and creativity within the jewelry industry.

2. Increased Customization: 3D printing enables jewelers to offer a wider range of customization options, allowing customers to personalize their jewelry with intricate details, unique engravings, and personalized gemstones. This personalized approach enhances customer satisfaction and creates a more intimate and meaningful connection with the jewelry piece.

3. Enhanced Design Capabilities: The ability to create complex designs and intricate details allows jewelers to explore new artistic expressions and push the boundaries of traditional jewelry design. This fosters a dynamic and innovative jewelry landscape, where artistic vision meets technological prowess.

4. Sustainable Practices: The reduced material waste and energy consumption associated with 3D printing align with the growing emphasis on sustainability within the jewelry industry. This promotes environmentally conscious practices and responsible sourcing of materials.

FAQs about 3D Printed Jewelry in Mount Pearl

1. What types of jewelry can be created using 3D printing?

3D printing can be used to create a wide range of jewelry pieces, including:

- Rings

- Earrings

- Pendants

- Bracelets

- Brooches

- Cufflinks

- Charms

- Custom designs

2. What materials can be used for 3D printed jewelry?

3D printing allows for the use of various materials, including:

- Precious metals (gold, silver, platinum)

- Resins (polymers)

- Ceramics

- Biocompatible materials

3. Is 3D printed jewelry durable?

3D printed jewelry can be as durable as traditionally crafted pieces, depending on the material and printing process used. Jewelers in Mount Pearl employ advanced techniques and high-quality materials to ensure the durability and longevity of their 3D printed jewelry.

4. How does 3D printing affect the cost of jewelry?

3D printing can potentially reduce the cost of jewelry production, particularly for complex designs or small-batch production. However, the cost can vary depending on the material, complexity of the design, and the jeweler’s pricing structure.

5. Can I design my own 3D printed jewelry?

Yes, jewelers in Mount Pearl often collaborate with clients to create custom designs. They can help translate your ideas into digital models and create a unique piece that reflects your personal style.

Tips for Choosing 3D Printed Jewelry in Mount Pearl

1. Research the Jeweler: Look for jewelers who have experience and expertise in 3D printing technology. Ensure they use high-quality materials and advanced printing processes to guarantee the durability and quality of their jewelry.

2. Consider the Design: Explore a variety of 3D printed designs and choose a piece that resonates with your personal style and aesthetic preferences. Don’t be afraid to think outside the box and explore unique and innovative designs.

3. Ask About Materials: Inquire about the materials used for the 3D printed jewelry and their properties. Understand the durability, finish, and potential care requirements for each material.

4. Request a Consultation: Schedule a consultation with the jeweler to discuss your design ideas and explore the possibilities of 3D printed jewelry. This allows for personalized guidance and ensures that the final piece meets your expectations.

5. Consider the Sustainability Aspect: Inquire about the jeweler’s commitment to sustainable practices and responsible sourcing of materials. Choose a jeweler who prioritizes environmental responsibility and ethical sourcing.

Conclusion

3D printing technology is revolutionizing the jewelry industry in Mount Pearl, empowering jewelers to create unique, personalized, and sustainable pieces that cater to the diverse tastes of their customers. By embracing this innovative technology, jewelers in Mount Pearl are pushing the boundaries of design, promoting artistic expression, and shaping the future of jewelry creation. As 3D printing technology continues to evolve, it promises to unlock even more possibilities for the world of jewelry, creating an exciting and dynamic landscape for both jewelers and their clients.

Closure

Thus, we hope this article has provided valuable insights into The Future of Jewelry Design: 3D Printing in Mount Pearl. We thank you for taking the time to read this article. See you in our next article!