The Rise Of 3D Jewelry Printing: A Comprehensive Guide To The Technology And Available Options

The Rise of 3D Jewelry Printing: A Comprehensive Guide to the Technology and Available Options

Related Articles: The Rise of 3D Jewelry Printing: A Comprehensive Guide to the Technology and Available Options

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to The Rise of 3D Jewelry Printing: A Comprehensive Guide to the Technology and Available Options. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Rise of 3D Jewelry Printing: A Comprehensive Guide to the Technology and Available Options

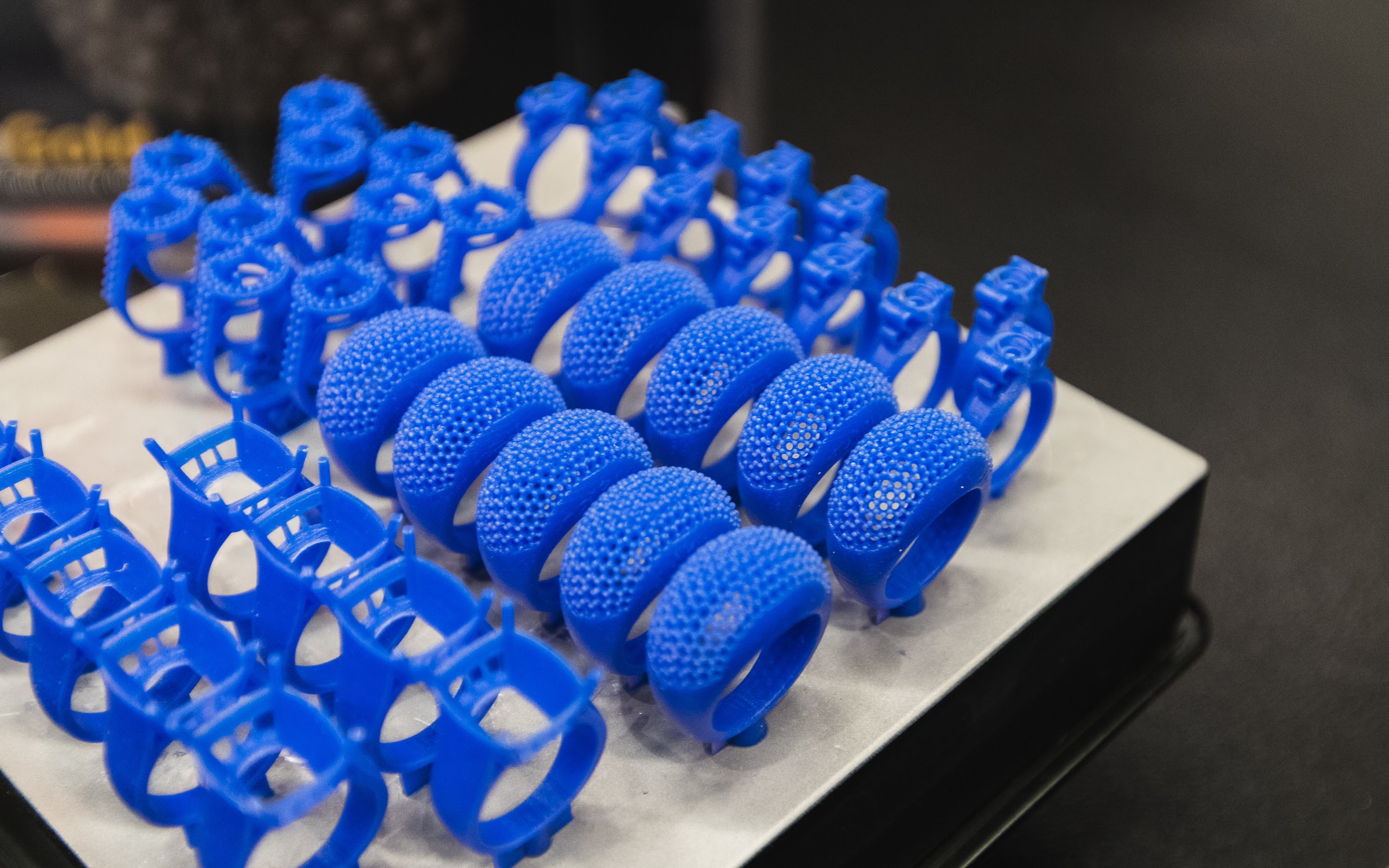

The jewelry industry is undergoing a revolution, driven by the advent of 3D printing technology. This transformative technology allows designers and artisans to create intricate and personalized pieces with unprecedented ease and precision. 3D jewelry printers are no longer a futuristic concept; they are readily available, offering a plethora of benefits for both established jewelers and aspiring creatives.

This comprehensive guide explores the world of 3D jewelry printers, encompassing their functionalities, advantages, types, and considerations for purchasing. We delve into the diverse range of models available, addressing the needs of different users, from hobbyists to professional jewelry makers.

Understanding the Fundamentals of 3D Jewelry Printing

3D jewelry printing, also known as additive manufacturing, involves building three-dimensional objects layer by layer from a digital design. This process utilizes a computer-aided design (CAD) software to create the virtual model, which is then translated into instructions for the 3D printer. The printer meticulously deposits material, typically a specialized resin or metal, onto a platform, solidifying each layer to form the final piece.

Advantages of 3D Jewelry Printing

The adoption of 3D printing in jewelry creation offers a multitude of advantages:

- Unparalleled Design Freedom: 3D printing empowers jewelers to realize intricate designs with complex geometries and organic shapes, previously impossible with traditional methods.

- Customization and Personalization: The technology allows for the creation of unique, bespoke jewelry pieces tailored to individual preferences, making each piece truly special.

- Rapid Prototyping: 3D printing enables rapid prototyping, allowing designers to experiment with different designs and iterate quickly, minimizing time and costs.

- Reduced Waste and Material Costs: 3D printing minimizes material waste compared to traditional casting methods, contributing to a more sustainable approach to jewelry production.

- Increased Efficiency and Productivity: 3D printing streamlines the jewelry production process, reducing lead times and increasing overall efficiency.

- Accessibility and Affordability: The availability of affordable 3D printers has opened doors for aspiring jewelers and small businesses, allowing them to enter the industry with lower startup costs.

Types of 3D Jewelry Printers

The market offers a diverse range of 3D printers specifically designed for jewelry creation. These printers are categorized based on the printing technology and materials used:

- Resin-Based 3D Printers: These printers utilize photopolymer resins, which are cured layer by layer using UV light. They offer high resolution and detail, making them ideal for intricate jewelry designs.

- Metal 3D Printers: These printers employ various metal powder sintering techniques, allowing for the creation of durable and high-quality jewelry pieces in precious metals like gold, silver, and platinum.

- Wax 3D Printers: These printers utilize wax as the printing material, creating models for the lost wax casting method. They are commonly used for creating intricate jewelry designs for mass production.

Factors to Consider When Choosing a 3D Jewelry Printer

Selecting the right 3D printer for your needs requires careful consideration of several factors:

- Printing Technology: Determine the printing technology that best suits your design requirements and budget.

- Material Compatibility: Choose a printer compatible with the desired materials, such as resin, metal, or wax.

- Resolution and Detail: Consider the level of detail required for your jewelry designs.

- Print Size: Ensure the printer’s build volume accommodates the size of your intended pieces.

- Software Compatibility: Verify compatibility with your preferred CAD software.

- Ease of Use: Look for user-friendly interfaces and intuitive controls.

- Cost: Consider the initial purchase price, running costs, and material costs.

Popular 3D Jewelry Printers for Sale

The market offers a wide range of 3D jewelry printers catering to different budgets and needs. Here are some popular models:

Resin-Based 3D Printers:

- Formlabs Form 3: Renowned for its high resolution and precision, the Form 3 offers excellent detail and surface finish, making it suitable for intricate jewelry designs.

- Anycubic Photon Mono X: This printer boasts a large build volume and fast printing speeds, ideal for both small and large jewelry pieces.

- Elegoo Mars 2: This affordable printer provides good value for money, offering high resolution and user-friendly features.

Metal 3D Printers:

- EOS M 290: This industrial-grade printer offers high precision and durability, suitable for professional jewelry makers.

- Renishaw AM250: This printer utilizes a laser melting process to create intricate metal jewelry pieces with fine details.

- Desktop Metal Studio System: This desktop metal printer provides an accessible entry point for small businesses and individuals interested in metal 3D printing.

Wax 3D Printers:

- EnvisionTEC Perfactory: This printer utilizes a high-precision wax printing technology, ideal for creating intricate models for lost wax casting.

- 3D Systems ProJet: This printer offers a wide range of wax materials and build volumes, suitable for both small and large jewelry pieces.

FAQs about 3D Jewelry Printers

1. What is the learning curve for using a 3D jewelry printer?

The learning curve varies depending on the printer’s complexity and your prior experience with 3D printing. Basic resin-based printers are relatively user-friendly and can be learned quickly. Metal 3D printers, however, require more specialized knowledge and training.

2. What are the ongoing costs associated with using a 3D jewelry printer?

Besides the initial purchase price, you need to factor in the cost of materials, maintenance, and software licenses. Resin, metal powder, and wax materials vary in price depending on the type and quality.

3. Can I create jewelry using my own designs?

Yes, 3D jewelry printers allow you to create jewelry based on your own designs. You can utilize CAD software to create virtual models and then print them using the printer.

4. What are the limitations of 3D jewelry printing?

While 3D printing offers immense possibilities, it has certain limitations. The build volume of the printer may restrict the size of the jewelry piece, and the material properties may limit the durability and wear resistance of the final product.

5. Is 3D jewelry printing suitable for mass production?

For small-scale production runs, 3D printing can be highly efficient. However, for mass production, traditional casting methods may still be more cost-effective.

Tips for Successful 3D Jewelry Printing

- Invest in high-quality materials: Using premium materials ensures superior results and durability.

- Optimize your print settings: Experiment with different print settings to find the optimal balance between speed, resolution, and material usage.

- Post-process your prints: After printing, carefully clean and polish your jewelry pieces to achieve a professional finish.

- Consider outsourcing: If you lack the necessary skills or equipment, consider outsourcing the post-processing steps to specialized service providers.

- Stay informed about advancements: The 3D printing industry is constantly evolving. Stay updated on the latest technology and materials to enhance your capabilities.

Conclusion

3D jewelry printing has revolutionized the jewelry industry, offering a myriad of benefits for designers, artisans, and businesses. From unprecedented design freedom to increased efficiency and sustainability, 3D printing empowers jewelers to create unique and personalized pieces. As the technology continues to advance, 3D jewelry printing is poised to play an even greater role in shaping the future of the jewelry industry. By carefully considering your needs and exploring the diverse range of printers available, you can harness the power of 3D printing to elevate your jewelry creations to new heights.

Closure

Thus, we hope this article has provided valuable insights into The Rise of 3D Jewelry Printing: A Comprehensive Guide to the Technology and Available Options. We thank you for taking the time to read this article. See you in our next article!