The Rise Of 3D Jewelry Printing: A Revolution In Design And Production

The Rise of 3D Jewelry Printing: A Revolution in Design and Production

Related Articles: The Rise of 3D Jewelry Printing: A Revolution in Design and Production

Introduction

With enthusiasm, let’s navigate through the intriguing topic related to The Rise of 3D Jewelry Printing: A Revolution in Design and Production. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Rise of 3D Jewelry Printing: A Revolution in Design and Production

The jewelry industry, known for its intricate craftsmanship and timeless appeal, is undergoing a transformative shift with the advent of 3D printing technology. 3D jewelry printers offer a revolutionary approach to design and production, enabling the creation of unique, personalized, and complex pieces with unprecedented precision and efficiency. This article delves into the intricacies of 3D jewelry printing, exploring its capabilities, benefits, and the profound impact it is having on the jewelry landscape.

Understanding 3D Jewelry Printing

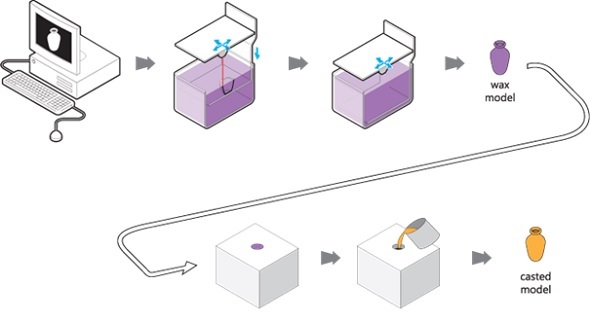

3D jewelry printing, also known as additive manufacturing, utilizes a computer-aided design (CAD) model to build jewelry pieces layer by layer. The process involves depositing a liquid or powdered material, often a specialized resin or wax, onto a platform, solidifying each layer to create the desired three-dimensional form. This meticulous layering technique allows for the creation of intricate designs, delicate details, and complex geometries that would be challenging or impossible to achieve using traditional methods.

Types of 3D Jewelry Printers

The world of 3D jewelry printing encompasses a diverse range of technologies, each with its unique capabilities and applications:

-

Stereolithography (SLA): This technology uses a vat of photopolymer resin that is selectively cured by a UV laser beam, solidifying each layer to form the desired shape. SLA printers are known for their high resolution and excellent surface finish, making them ideal for intricate designs and delicate pieces.

-

Digital Light Processing (DLP): Similar to SLA, DLP utilizes a projector to shine a UV light onto a vat of resin, curing specific areas to create layers. DLP printers offer faster printing speeds compared to SLA, making them suitable for larger jewelry pieces or production runs.

-

Fused Deposition Modeling (FDM): This technology uses a thermoplastic filament that is heated and extruded through a nozzle, depositing layers of material onto a build platform. FDM printers are known for their versatility and affordability, making them popular for prototyping and producing jewelry in various materials, including wax, plastic, and even precious metals.

-

Selective Laser Sintering (SLS): SLS printers use a laser to fuse powdered materials, such as nylon or metal, layer by layer. This process allows for the creation of strong and durable jewelry pieces with complex geometries and intricate details.

-

Direct Metal Laser Sintering (DMLS): DMLS technology utilizes a high-powered laser to fuse powdered metal, creating dense and durable jewelry pieces. This process is particularly suitable for creating high-quality jewelry in precious metals like gold, silver, and platinum.

Benefits of 3D Jewelry Printing

The adoption of 3D printing technology within the jewelry industry brings forth a plethora of benefits, revolutionizing design, production, and ultimately, the customer experience:

-

Design Freedom and Customization: 3D printing liberates jewelry designers from the constraints of traditional methods, allowing them to explore complex geometries, intricate patterns, and personalized designs. This empowers them to create truly unique pieces that cater to individual tastes and preferences.

-

Rapid Prototyping and Iteration: 3D printing enables rapid prototyping, allowing designers to quickly visualize and iterate on their designs. This iterative process accelerates the design cycle, facilitating the creation of refined and optimized jewelry pieces.

-

Reduced Production Costs: 3D printing eliminates the need for expensive molds and tooling, significantly reducing production costs. This makes it particularly attractive for small-scale jewelry businesses and independent designers, allowing them to compete effectively in the market.

-

Enhanced Detail and Precision: 3D printing offers exceptional detail and precision, capturing the intricate details of designs with remarkable accuracy. This allows for the creation of intricate filigree work, delicate textures, and intricate settings that would be challenging to achieve using traditional methods.

-

Personalized Jewelry: 3D printing empowers customers to create personalized jewelry pieces that reflect their unique style and preferences. From custom engravings and personalized gemstones to intricate designs incorporating personal symbols, 3D printing opens up a world of possibilities for bespoke jewelry.

-

Sustainable Production: 3D printing reduces material waste compared to traditional jewelry manufacturing methods. This environmentally conscious approach aligns with growing consumer demand for sustainable and ethical products.

Applications of 3D Jewelry Printing

3D jewelry printing finds application across various aspects of the jewelry industry, from design and prototyping to production and customization:

-

Prototyping and Design Exploration: 3D printing enables designers to quickly create prototypes of their jewelry designs, allowing them to visualize and refine their ideas before investing in expensive molds or tooling.

-

Production of Unique Pieces: 3D printing empowers jewelry makers to create unique and limited-edition pieces, catering to a niche market seeking distinctive and personalized jewelry.

-

Custom Jewelry Design: 3D printing allows for the creation of personalized jewelry, incorporating customer-specific designs, engravings, and settings.

-

Production of Complex Designs: 3D printing enables the creation of intricate designs that would be impossible or challenging to achieve using traditional methods, such as filigree work, delicate textures, and complex settings.

-

Production of Jewelry in Various Materials: 3D printing can be used to create jewelry in a wide range of materials, including wax, plastic, precious metals, and even ceramics.

Challenges and Considerations

While 3D jewelry printing offers numerous advantages, it also presents certain challenges and considerations:

-

Material Limitations: The choice of materials available for 3D jewelry printing is still limited compared to traditional jewelry manufacturing methods. However, research and development are constantly expanding the range of materials available.

-

Post-Processing Requirements: Some 3D printed jewelry pieces may require post-processing steps, such as sanding, polishing, or finishing, to achieve the desired aesthetic and durability.

-

Scaling Production: Scaling up 3D jewelry printing for mass production can be challenging, requiring significant investment in equipment and infrastructure.

-

Intellectual Property Protection: The ease with which 3D printed designs can be replicated raises concerns about intellectual property protection.

The Future of 3D Jewelry Printing

The future of 3D jewelry printing holds immense potential for innovation and growth. Advancements in materials science, printing technologies, and software are constantly pushing the boundaries of what is possible. Key areas of development include:

-

New Materials: Research and development are focusing on creating new materials specifically for 3D jewelry printing, including biocompatible materials, high-performance metals, and materials with unique aesthetic properties.

-

Improved Resolution and Accuracy: Advancements in printing technologies are continuously improving resolution and accuracy, enabling the creation of even more intricate and detailed jewelry pieces.

-

Automated Production: The development of automated 3D printing systems is streamlining the production process, enabling higher throughput and reduced labor costs.

-

Integration with Artificial Intelligence (AI): AI-powered tools are being developed to assist designers in creating optimized jewelry designs, automating aspects of the design process, and enhancing the overall efficiency of 3D jewelry printing.

FAQs about 3D Jewelry Printing

Q: What are the common materials used in 3D jewelry printing?

A: Common materials used in 3D jewelry printing include:

-

Resins: Photopolymer resins are widely used in SLA and DLP printing, offering a wide range of colors, finishes, and properties.

-

Wax: Wax is commonly used in FDM printing for creating wax models that can be used in lost wax casting.

-

Plastics: Various plastics, including ABS, PLA, and nylon, are used in FDM printing for creating prototypes and jewelry pieces in a variety of colors and finishes.

-

Metals: Metals, such as silver, gold, platinum, and stainless steel, are used in DMLS and SLS printing for creating durable and high-quality jewelry pieces.

Q: What are the advantages of using 3D printing for jewelry production?

A: The advantages of using 3D printing for jewelry production include:

-

Design Freedom: 3D printing allows for the creation of complex and intricate designs that would be impossible or challenging to achieve using traditional methods.

-

Rapid Prototyping: 3D printing enables designers to quickly create prototypes of their designs, allowing for rapid iteration and refinement.

-

Reduced Costs: 3D printing eliminates the need for expensive molds and tooling, significantly reducing production costs.

-

Enhanced Detail and Precision: 3D printing offers exceptional detail and precision, capturing the intricate details of designs with remarkable accuracy.

-

Customization: 3D printing enables the creation of personalized jewelry pieces that reflect individual tastes and preferences.

Q: What are the limitations of 3D jewelry printing?

A: The limitations of 3D jewelry printing include:

-

Material Limitations: The choice of materials available for 3D jewelry printing is still limited compared to traditional methods.

-

Post-Processing Requirements: Some 3D printed jewelry pieces may require post-processing steps, such as sanding, polishing, or finishing.

-

Scaling Production: Scaling up 3D jewelry printing for mass production can be challenging, requiring significant investment in equipment and infrastructure.

Q: How does 3D jewelry printing affect the jewelry industry?

A: 3D jewelry printing is transforming the jewelry industry by:

-

Empowering independent designers: 3D printing makes it easier for independent designers to create and sell their own jewelry, increasing competition and innovation.

-

Creating new design possibilities: 3D printing allows for the creation of intricate and complex designs that were previously impossible, pushing the boundaries of jewelry design.

-

Making jewelry more affordable: 3D printing reduces production costs, making jewelry more accessible to a wider range of consumers.

-

Enhancing sustainability: 3D printing reduces material waste and energy consumption, contributing to a more sustainable jewelry industry.

Tips for Choosing a 3D Jewelry Printer

When choosing a 3D jewelry printer, consider the following factors:

-

Type of Printing Technology: Different printing technologies offer different capabilities and limitations. Choose a technology that aligns with your specific needs and design requirements.

-

Material Compatibility: Ensure the printer is compatible with the materials you plan to use.

-

Print Resolution and Accuracy: Higher resolution and accuracy result in finer details and a better finish.

-

Build Volume: Choose a printer with a build volume that is sufficient for the size of your jewelry pieces.

-

Printing Speed: Consider the printing speed of the printer, especially if you plan to produce jewelry in large quantities.

-

Cost: 3D printers vary significantly in price. Consider your budget and the return on investment.

Conclusion

3D jewelry printing is reshaping the jewelry industry, offering unparalleled design freedom, customization, and production efficiency. As technology continues to advance, the possibilities for 3D jewelry printing are boundless, promising a future where intricate designs, personalized pieces, and sustainable practices become the norm. The adoption of this revolutionary technology empowers both designers and consumers, ushering in a new era of creativity, innovation, and personalized luxury in the world of jewelry.

Closure

Thus, we hope this article has provided valuable insights into The Rise of 3D Jewelry Printing: A Revolution in Design and Production. We appreciate your attention to our article. See you in our next article!