The Rise Of 3D Jewelry Printing: Revolutionizing The Art Of Adornment

The Rise of 3D Jewelry Printing: Revolutionizing the Art of Adornment

Related Articles: The Rise of 3D Jewelry Printing: Revolutionizing the Art of Adornment

Introduction

With great pleasure, we will explore the intriguing topic related to The Rise of 3D Jewelry Printing: Revolutionizing the Art of Adornment. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Rise of 3D Jewelry Printing: Revolutionizing the Art of Adornment

The world of jewelry has undergone a dramatic transformation with the advent of 3D printing technology. This innovative process, also known as additive manufacturing, has empowered jewelers and designers to transcend traditional limitations, ushering in a new era of creativity and customization.

Understanding 3D Jewelry Printing: A Technological Leap

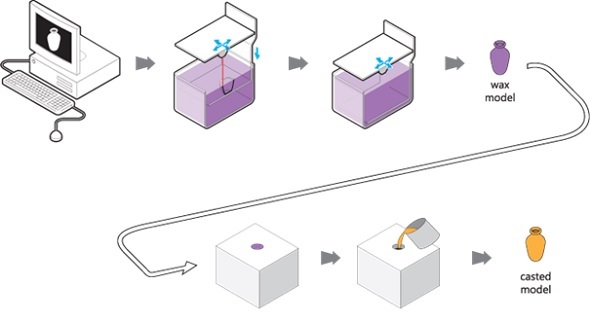

3D jewelry printing employs a layered approach to build intricate designs from digital models. The process begins with a 3D design software where jewelers meticulously craft their creations, fine-tuning every detail from the shape and size to the intricate patterns and textures. This digital blueprint is then translated into instructions for the 3D printer.

The printer utilizes a variety of materials, ranging from precious metals like gold and silver to resins, waxes, and even ceramics. It meticulously lays down thin layers of these materials, following the instructions provided by the digital model. This layer-by-layer construction technique, akin to building a tower with blocks, gradually gives rise to the final jewelry piece.

Advantages of 3D Jewelry Printing: Unveiling a New Era of Design and Production

The impact of 3D printing on jewelry design and production is undeniable. Its benefits extend across various aspects, including:

-

Unparalleled Customization: 3D printing empowers jewelers to create highly personalized pieces, catering to individual preferences and unique styles. From intricate engravings to custom-fit rings, the possibilities are virtually limitless.

-

Enhanced Design Freedom: The technology liberates designers from the constraints of traditional jewelry-making techniques. Complex geometries, intricate filigree, and intricate patterns can be easily incorporated into designs, pushing the boundaries of creativity.

-

Reduced Production Costs: 3D printing eliminates the need for expensive molds and casting processes, making it a cost-effective solution for both large-scale production and small-scale, bespoke pieces.

-

Rapid Prototyping: 3D printing facilitates rapid prototyping, allowing jewelers to quickly visualize and refine their designs before committing to a final production run. This iterative process fosters innovation and experimentation.

-

Sustainable Practices: 3D printing reduces waste generated during traditional jewelry production, promoting environmentally conscious practices within the industry.

Materials Used in 3D Jewelry Printing: A Diverse Palette for Creative Expression

The choice of materials for 3D jewelry printing is crucial for achieving the desired aesthetic and functionality. The most commonly used materials include:

-

Precious Metals: Gold, silver, platinum, and other precious metals can be used in 3D printing, providing a luxurious and timeless appeal to jewelry pieces.

-

Resins: Photopolymer resins offer a wide range of colors, textures, and finishes, making them ideal for intricate and detailed designs.

-

Waxes: Wax is a popular material for lost wax casting, where a 3D printed wax model is used to create a mold for casting in metal.

-

Ceramics: 3D printing with ceramics enables the creation of unique and durable jewelry pieces with a sophisticated and elegant finish.

Applications of 3D Jewelry Printing: A Spectrum of Possibilities

3D printing has revolutionized various aspects of the jewelry industry, finding applications in:

-

Custom Jewelry Design: Creating personalized pieces for individuals, including engagement rings, wedding bands, and personalized pendants.

-

Mass Customization: Offering a range of customizable jewelry options, allowing customers to personalize their pieces with unique elements and designs.

-

Limited Edition Collections: Creating unique and limited-edition jewelry pieces, adding exclusivity and value to the collection.

-

Prototyping and Design Exploration: Rapidly prototyping new designs and exploring different options before committing to production.

-

Production of Intricate Jewelry: Creating complex and detailed jewelry pieces that would be difficult or impossible to manufacture using traditional techniques.

FAQs on 3D Jewelry Printing: Addressing Common Queries

1. Is 3D printed jewelry durable?

The durability of 3D printed jewelry depends on the material used and the printing process. Precious metals like gold and silver offer exceptional durability, while resins and ceramics offer varying levels of strength and resilience.

2. Can 3D printed jewelry be resized?

Resizing 3D printed jewelry can be challenging, especially for intricate designs. It’s best to consult with the jeweler or designer about resizing options before purchasing.

3. How long does it take to 3D print jewelry?

The printing time varies depending on the complexity of the design, the material used, and the size of the piece. Smaller and simpler designs can be printed within hours, while more intricate pieces may take several days.

4. Is 3D printed jewelry expensive?

The cost of 3D printed jewelry varies depending on the material, complexity of the design, and the jeweler’s pricing. While 3D printing can be cost-effective for some pieces, certain materials and intricate designs may come at a premium.

5. Can I design my own jewelry to be 3D printed?

Many jewelers and designers offer custom design services, allowing you to create your own jewelry pieces to be 3D printed. Some online platforms also provide tools for designing and ordering 3D printed jewelry.

Tips for Choosing 3D Printed Jewelry:

-

Consider the Material: Choose a material that aligns with your preferences and budget. Precious metals offer durability and prestige, while resins and ceramics offer unique aesthetics and affordability.

-

Seek Expertise: Consult with experienced jewelers or designers specializing in 3D printing to ensure quality craftsmanship and design execution.

-

Explore Customization Options: Embrace the opportunity to personalize your jewelry with custom engravings, stones, or design elements.

-

Request Samples: If possible, request samples or view previous works to assess the jeweler’s expertise and craftsmanship.

-

Compare Prices: Compare prices from different jewelers to find the best value for your desired piece.

Conclusion: 3D Jewelry Printing – A Catalyst for Innovation and Creativity

3D printing has revolutionized the jewelry industry, transforming how designers create, jewelers manufacture, and customers acquire their cherished adornments. This transformative technology has unlocked a realm of possibilities, empowering jewelers to push creative boundaries and customers to express their individual style with unparalleled personalization. As the technology continues to evolve, we can expect even more innovative applications and breathtaking designs to emerge, further solidifying 3D printing’s place as a cornerstone of the jewelry industry.

Closure

Thus, we hope this article has provided valuable insights into The Rise of 3D Jewelry Printing: Revolutionizing the Art of Adornment. We thank you for taking the time to read this article. See you in our next article!