The Rise Of 3D Jewelry Printing: Revolutionizing The Art Of Adornment

The Rise of 3D Jewelry Printing: Revolutionizing the Art of Adornment

Related Articles: The Rise of 3D Jewelry Printing: Revolutionizing the Art of Adornment

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to The Rise of 3D Jewelry Printing: Revolutionizing the Art of Adornment. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Rise of 3D Jewelry Printing: Revolutionizing the Art of Adornment

The world of jewelry design has undergone a dramatic transformation with the advent of 3D printing technology. Once confined to traditional casting and fabrication methods, jewelry creation is now being redefined by the precision, versatility, and creative freedom offered by 3D printing. This technology empowers jewelers, designers, and even hobbyists to craft intricate and unique pieces with unprecedented ease and accuracy.

Understanding 3D Jewelry Printing

3D jewelry printing, also known as additive manufacturing, utilizes a digital design file to build three-dimensional objects layer by layer. This process involves a specialized 3D printer that extrudes or solidifies material, typically resin, wax, or metal, according to the design data. The resulting piece is a physical manifestation of the digital model, capturing even the most intricate details.

The Advantages of 3D Jewelry Printing

The adoption of 3D printing in jewelry creation has brought about a paradigm shift, offering numerous advantages over traditional methods:

- Unparalleled Design Freedom: 3D printing liberates designers from the constraints of traditional techniques. Complex geometries, intricate patterns, and bespoke designs become readily achievable, allowing for the creation of truly unique and personalized pieces.

- Rapid Prototyping: The ability to quickly iterate and experiment with different designs is a significant advantage. 3D printing allows jewelers to create multiple prototypes in a short timeframe, facilitating rapid design refinement and optimization.

- Cost-Effectiveness: 3D printing eliminates the need for costly molds and tooling, making it a more economical option, especially for small-scale production runs or customized pieces. This affordability opens up opportunities for independent designers and small businesses.

- Reduced Waste: Traditional jewelry manufacturing often involves significant material waste. 3D printing, being an additive process, uses only the necessary material, minimizing waste and promoting sustainable practices.

- Customization and Personalization: 3D printing empowers customers to actively participate in the design process, creating truly personalized pieces that reflect their individual style and preferences. This fosters a sense of ownership and connection with the jewelry.

- Precision and Detail: 3D printing offers unparalleled accuracy and detail, enabling the creation of intricate designs and delicate features that would be challenging or impossible to achieve using traditional methods.

Types of 3D Jewelry Printers

Several types of 3D printers are employed in jewelry creation, each with its unique characteristics and applications:

- Resin 3D Printers: These printers use a liquid resin that is cured by a UV light source, layer by layer, to create intricate and detailed pieces. Resin printing is ideal for prototyping and creating delicate designs.

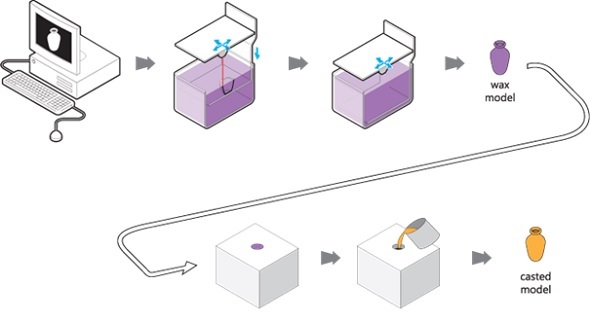

- Wax 3D Printers: Wax printing is widely used for lost wax casting, a traditional jewelry making method. The 3D printed wax model is used to create a mold, which is then filled with molten metal to produce the final piece.

- Metal 3D Printers: These printers use various metal powders or wires that are fused together using lasers or electron beams to create solid metal objects. Metal 3D printing enables the creation of high-quality, durable, and intricate jewelry pieces.

Materials Used in 3D Jewelry Printing

The choice of material for 3D jewelry printing depends on the desired properties, aesthetics, and application of the piece. Common materials include:

- Resins: Photopolymer resins offer a wide range of colors, textures, and finishes. They are suitable for prototyping and creating intricate details.

- Wax: Wax is the preferred material for lost wax casting, allowing for the creation of intricate designs and delicate features.

- Metals: 3D printing allows for the use of a wide range of metals, including gold, silver, platinum, and stainless steel, enabling the creation of high-quality and durable jewelry pieces.

- Ceramics: Ceramic 3D printing is gaining traction in jewelry creation, offering unique aesthetic possibilities and durability.

The Process of 3D Jewelry Printing

The process of 3D jewelry printing involves several steps:

- Design: The jewelry design is created using computer-aided design (CAD) software. This allows for precise control over every aspect of the piece, from its shape and size to its intricate details.

- Slicing: The 3D model is sliced into thin horizontal layers using a dedicated software program. These layers form the blueprint for the 3D printer.

- Printing: The sliced data is sent to the 3D printer, which extrudes or solidifies material, layer by layer, according to the design.

- Post-Processing: Depending on the printing technology and material used, post-processing may be required. This can include cleaning, sanding, polishing, and finishing to achieve the desired look and feel.

The Impact of 3D Jewelry Printing

The widespread adoption of 3D printing in jewelry creation has had a profound impact on the industry:

- Democratization of Design: 3D printing has made jewelry design accessible to a wider audience, empowering independent designers and small businesses to compete with established players.

- Increased Customization: Customers now have the opportunity to personalize their jewelry, creating pieces that reflect their unique style and preferences.

- Enhanced Sustainability: 3D printing reduces material waste and promotes sustainable manufacturing practices.

- Innovation and Experimentation: 3D printing encourages experimentation and innovation, pushing the boundaries of jewelry design and creating new possibilities.

FAQs about 3D Jewelry Printing

Q: Is 3D printed jewelry durable?

A: The durability of 3D printed jewelry depends on the printing technology, material used, and post-processing techniques. Resin-based jewelry may be more prone to scratching or chipping, while metal 3D printed jewelry is known for its durability and longevity.

Q: Is 3D printed jewelry expensive?

A: The cost of 3D printed jewelry can vary depending on the design complexity, material used, and production volume. However, 3D printing can often be more cost-effective than traditional methods, especially for small-scale production runs or customized pieces.

Q: How long does it take to 3D print jewelry?

A: The printing time depends on the size and complexity of the design, as well as the printing technology used. Simple pieces can be printed in a few hours, while more intricate designs may take several days.

Q: Can I design my own 3D printed jewelry?

A: Yes, there are many user-friendly CAD software programs available that allow you to design your own jewelry. You can then send your design to a 3D printing service or use your own 3D printer to create your unique piece.

Tips for Designing and Printing 3D Jewelry

- Consider the material: Choose a material that is suitable for the desired aesthetic, durability, and application of the piece.

- Simplify the design: Avoid overly intricate designs that may be challenging to print or may require extensive post-processing.

- Use supports: For complex designs, consider using supports to prevent sagging or deformation during the printing process.

- Optimize the print settings: Experiment with different print settings, such as layer height, infill density, and printing speed, to achieve the desired results.

- Post-process carefully: Post-processing is crucial for achieving the desired finish and durability.

Conclusion

3D jewelry printing has revolutionized the art of adornment, empowering designers, jewelers, and hobbyists to create unique and personalized pieces with unprecedented ease and accuracy. This technology offers unparalleled design freedom, rapid prototyping, cost-effectiveness, and enhanced sustainability, making it a transformative force in the jewelry industry. As 3D printing technology continues to evolve, we can expect even more innovative and exciting advancements in jewelry design and creation.

Closure

Thus, we hope this article has provided valuable insights into The Rise of 3D Jewelry Printing: Revolutionizing the Art of Adornment. We thank you for taking the time to read this article. See you in our next article!