The Rise of 3D Jewelry Printing: A Revolution in Design and Customization

Related Articles: The Rise of 3D Jewelry Printing: A Revolution in Design and Customization

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to The Rise of 3D Jewelry Printing: A Revolution in Design and Customization. Let’s weave interesting information and offer fresh perspectives to the readers.

The Rise of 3D Jewelry Printing: A Revolution in Design and Customization

The jewelry industry has witnessed a dramatic transformation in recent years, with the advent of 3D printing technology ushering in a new era of design possibilities and personalized creations. This innovative method, known as 3D jewelry printing, has empowered both established jewelers and independent artists alike, revolutionizing the way jewelry is conceived, designed, and manufactured.

Understanding 3D Jewelry Printing: A Technological Breakthrough

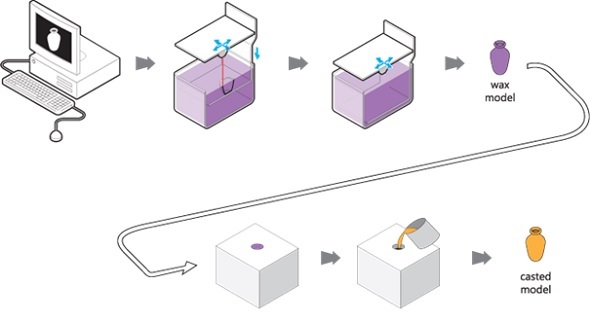

3D jewelry printing, also known as additive manufacturing, employs a sophisticated process to create intricate jewelry pieces from digital designs. Unlike traditional methods that rely on subtractive techniques like carving or casting, 3D printing builds objects layer by layer, enabling the creation of complex geometries and intricate details that were previously unattainable.

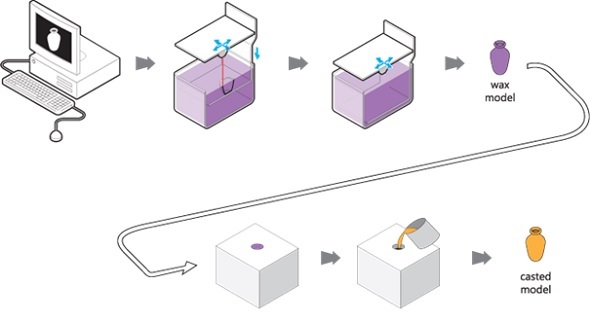

The process typically involves the following steps:

-

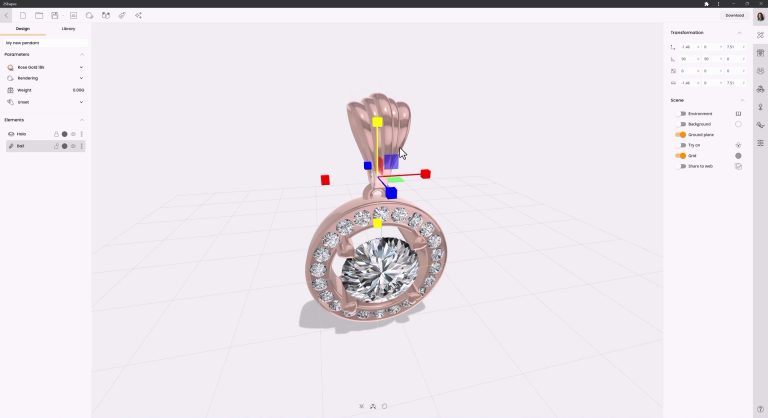

Design: The jewelry design is first created digitally using computer-aided design (CAD) software. This allows for precise control over every aspect of the piece, from its shape and size to the inclusion of intricate details and textures.

-

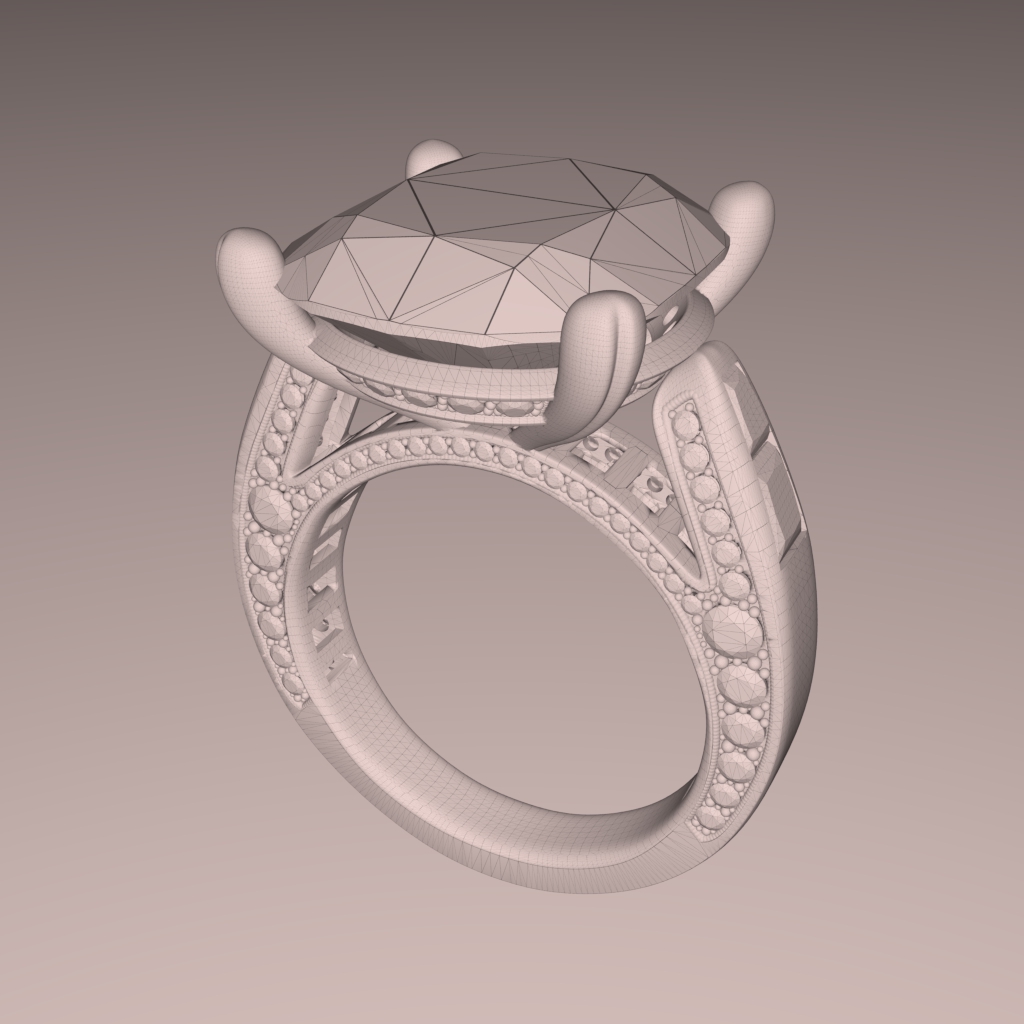

3D Model Creation: The digital design is then converted into a 3D model, which serves as the blueprint for the printing process. This model is typically saved in a standard file format like STL or OBJ.

-

Printing: The 3D model is then sent to a specialized 3D printer that uses a variety of materials, including wax, resin, metal, or even precious metals like gold and silver. The printer lays down successive layers of material, following the digital blueprint, until the final jewelry piece is complete.

-

Post-Processing: Depending on the printing material and desired finish, the printed piece may require post-processing steps such as smoothing, polishing, or setting gemstones.

The Advantages of 3D Jewelry Printing: A Paradigm Shift in Design and Production

The adoption of 3D jewelry printing has brought about a significant shift in the industry, offering numerous advantages over traditional methods:

1. Unparalleled Design Freedom: 3D printing unlocks limitless design possibilities, allowing jewelers to create pieces with intricate details, complex geometries, and unique textures that would be impossible to achieve through traditional methods. This opens up a new world of creative expression and enables the realization of even the most ambitious designs.

2. Enhanced Customization: 3D printing empowers customers to personalize their jewelry, creating pieces that are truly unique and reflect their individual style. From incorporating personal initials or special dates to designing custom engagement rings, the possibilities for customization are virtually endless.

3. Reduced Production Time and Cost: 3D printing significantly reduces the time and cost associated with jewelry production. Traditional methods often involve multiple steps and require specialized tools and expertise. 3D printing streamlines the process, allowing for faster turnaround times and lower overall costs, especially for small-scale production runs or customized pieces.

4. Reduced Material Waste: 3D printing utilizes only the necessary material to create the desired object, significantly reducing waste compared to traditional methods that involve carving or casting, where a significant amount of material is lost during the process. This makes 3D printing an environmentally friendly and sustainable option for jewelry production.

5. Prototyping and Experimentation: 3D printing enables rapid prototyping, allowing jewelers to create and test different designs quickly and efficiently. This facilitates experimentation and innovation, enabling the exploration of new shapes, textures, and materials without the cost and time constraints associated with traditional methods.

6. Increased Accessibility: 3D printing technology has become increasingly accessible, with a wide range of 3D printers available at various price points. This allows both small-scale jewelry businesses and independent designers to adopt the technology without significant upfront investments.

Applications of 3D Jewelry Printing: A Diverse Range of Possibilities

3D jewelry printing has found applications in a diverse range of areas, catering to various needs and preferences:

1. Custom Jewelry: 3D printing is ideal for creating unique and personalized jewelry pieces, from engagement rings and wedding bands to custom pendants and earrings. Customers can collaborate with designers to create pieces that reflect their individual style and preferences, resulting in truly one-of-a-kind creations.

2. Fine Jewelry: 3D printing is increasingly used for creating high-end jewelry pieces, especially those featuring intricate details and complex designs. The technology allows for the creation of delicate filigree work, intricate textures, and even the integration of gemstones in innovative ways.

3. Mass Customization: 3D printing allows for the creation of customized jewelry pieces at scale, enabling businesses to offer a wider range of options and cater to individual preferences. This allows for the production of personalized jewelry pieces without compromising on efficiency or cost-effectiveness.

4. Prototyping and Production: 3D printing is a valuable tool for jewelry prototyping, allowing designers to create physical models of their designs quickly and efficiently. This facilitates the testing of different designs and materials before committing to full-scale production.

5. Educational and Artistic Applications: 3D printing is also used in educational settings to teach students about jewelry design and production. Artists use the technology to create innovative and experimental jewelry pieces, pushing the boundaries of traditional design concepts.

The Future of 3D Jewelry Printing: A Promising Landscape

The future of 3D jewelry printing is bright, with ongoing advancements in technology and materials paving the way for even greater innovation and customization.

1. Advancements in Materials: Research and development efforts are continuously exploring new materials for 3D printing, including biocompatible materials for medical implants and functional materials for electronic applications. This will further expand the possibilities for creating unique and functional jewelry pieces.

2. Increased Accuracy and Resolution: 3D printers are becoming increasingly accurate and precise, allowing for the creation of jewelry pieces with finer details and more complex geometries. This will enhance the realism and aesthetic appeal of 3D printed jewelry, making it indistinguishable from traditionally crafted pieces.

3. Integration with Artificial Intelligence (AI): AI is being integrated into 3D printing workflows, enabling automated design optimization and personalized recommendations based on customer preferences. This will further streamline the design and production process, making it more efficient and user-friendly.

4. Sustainable and Ethical Practices: 3D printing promotes sustainable and ethical jewelry production by reducing material waste and minimizing environmental impact. The use of recycled materials and eco-friendly printing processes will further enhance the sustainability of the industry.

5. Growing Market Demand: The demand for personalized and unique jewelry is growing, driving the adoption of 3D printing technology. This will lead to increased investment in research and development, further accelerating the growth of the 3D jewelry printing market.

Frequently Asked Questions about 3D Jewelry Printing Services

1. What types of jewelry can be printed using 3D printing?

3D printing can be used to create a wide variety of jewelry pieces, including rings, earrings, pendants, bracelets, necklaces, and more. The type of jewelry that can be printed depends on the chosen printing material and the capabilities of the 3D printer.

2. What materials are used for 3D jewelry printing?

3D jewelry printing utilizes a range of materials, including:

-

Wax: Used for creating wax models for lost-wax casting.

-

Resin: Offers a wide range of colors and finishes, suitable for both fine and costume jewelry.

-

Metal: Allows for the creation of jewelry pieces from precious metals like gold, silver, and platinum.

-

Plastic: A cost-effective option for creating durable and lightweight jewelry pieces.

3. How long does it take to 3D print a jewelry piece?

The printing time for a jewelry piece varies depending on its size, complexity, and the chosen printing material. Simple pieces can be printed in a few hours, while more intricate designs may take several days.

4. How much does 3D jewelry printing cost?

The cost of 3D jewelry printing varies depending on the chosen material, the complexity of the design, and the printing service provider. Prices can range from a few hundred dollars to several thousand dollars, depending on the project.

5. Is 3D printed jewelry durable?

The durability of 3D printed jewelry depends on the chosen material and the printing process. Metal and resin jewelry pieces are generally durable and can withstand everyday wear and tear. However, plastic jewelry may be less durable and prone to scratches or breakage.

6. Can I design my own jewelry using 3D printing?

Yes, you can design your own jewelry using 3D printing. Many 3D printing services offer design tools and software that allow you to create your own designs. Alternatively, you can collaborate with a jewelry designer to create a custom piece.

7. How do I find a reputable 3D jewelry printing service?

When choosing a 3D jewelry printing service, consider factors such as:

-

Experience: Look for a service provider with experience in 3D jewelry printing and a proven track record.

-

Materials: Ensure the service provider offers a wide range of materials suitable for your project.

-

Quality: Review customer testimonials and portfolio to assess the quality of their work.

-

Customer Service: Choose a service provider that offers excellent customer service and is responsive to your needs.

8. What are the benefits of using a 3D jewelry printing service?

Using a 3D jewelry printing service offers several benefits, including:

-

Customization: Create unique and personalized jewelry pieces.

-

Design Freedom: Explore a wide range of design possibilities.

-

Faster Turnaround Times: Receive your jewelry pieces quickly and efficiently.

-

Reduced Costs: Benefit from competitive pricing and cost-effective solutions.

-

High Quality: Receive expertly crafted and polished jewelry pieces.

Tips for Choosing a 3D Jewelry Printing Service

When choosing a 3D jewelry printing service, it is crucial to carefully consider the following factors:

1. Material Options: Ensure the service provider offers a wide range of materials suitable for your project, including precious metals, resins, and plastics.

2. Design Capabilities: Verify that the service provider has the design expertise and software to handle complex designs and intricate details.

3. Quality Control: Inquire about the service provider’s quality control measures and their commitment to delivering high-quality jewelry pieces.

4. Customer Service: Choose a service provider that offers excellent customer service and is responsive to your inquiries and needs.

5. Pricing and Turnaround Times: Compare pricing and turnaround times from different service providers to find the best value for your project.

6. Reviews and Testimonials: Read online reviews and testimonials from previous customers to gauge the service provider’s reputation and customer satisfaction.

7. Security and Confidentiality: Ensure that the service provider has appropriate security measures in place to protect your designs and personal information.

8. Customization Options: Inquire about the service provider’s customization options, such as the ability to incorporate personal touches or create bespoke designs.

9. Prototyping and Design Assistance: If you need assistance with design or prototyping, look for a service provider that offers these services.

10. Warranty and Returns: Inquire about the service provider’s warranty and return policies in case of any issues with the printed jewelry piece.

Conclusion: The Future of Jewelry Creation

3D jewelry printing has revolutionized the jewelry industry, offering a range of benefits that have transformed the way jewelry is designed, manufactured, and consumed. From unparalleled design freedom and enhanced customization to reduced production times and costs, 3D printing has empowered jewelers, designers, and customers alike, opening up a world of possibilities for creating unique and personalized jewelry pieces. As technology continues to evolve and materials advance, 3D jewelry printing is poised to play an even greater role in shaping the future of the jewelry industry, offering a sustainable, innovative, and personalized approach to jewelry creation.

Closure

Thus, we hope this article has provided valuable insights into The Rise of 3D Jewelry Printing: A Revolution in Design and Customization. We appreciate your attention to our article. See you in our next article!